Nearly ten types of 3D printing equipment have been successfully developed to meet the market demand, and can be customized according to the specific needs of users. Safe and stable operation, fully open process parameters and set maintenance, spare parts, training in one of the whole life cycle of equipment after-sales service, make the product favored by customers.

Laser selective melting equipment LiM-X150A/X260 series /X400 series /X400H/X650 series /X650H

High reliability

Through outstanding modular design and lean management system, the manufacturing consistency of the final equipment is achieved. Several X series equipment produced by Radium Laser have passed the most stringent tests of industrial customers such as aerospace.

customizable

Series of equipment adopts modular design, can be customized according to customer needs of laser power, galvanometer number, forming size, monitoring module, each module independent design, widely used in the series of products, good reliability, customized products and standard product stability.

Reduce total cost of ownership for customers

Through optimized processes and specially designed systems, the equipment can help customers reduce powder and inert gas consumption, and achieve a lower operating cost. At the same time, the software designed by man-machine engineering is very easy to use, reducing the difficulty of learning equipment operators. We also have a consulting team with more than 10 years of experience in additive manufacturing, which can help customers optimize the process and improve the product qualification rate.

safety

Work safety is the most important standard of laser. All the equipment of Radium Ming has passed the safety certification, the relevant certification standards include EN60079-0:212 +A11:2013, and EN60079-2:214.

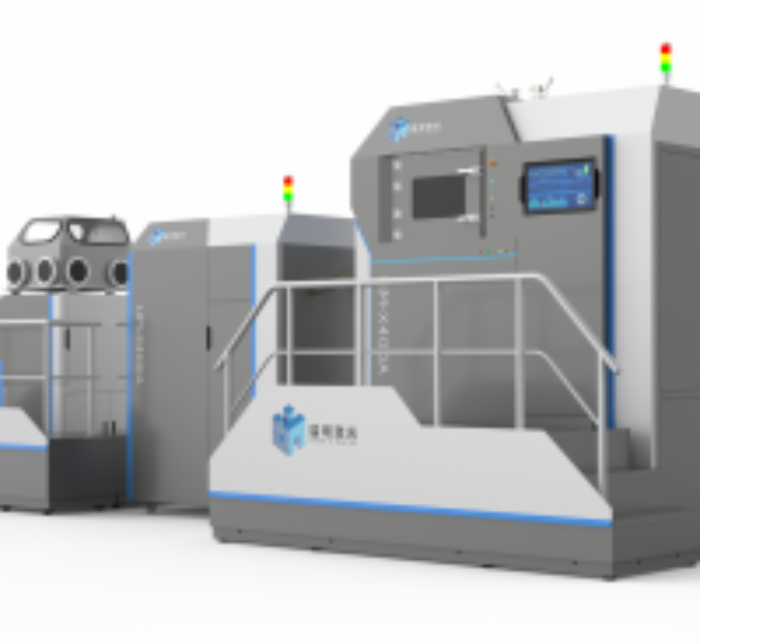

Laser near net forming equipment LiM-S0402/S1006/S2510/S4510

Excellent quality and high reliability

Through years of practical application verification, equipment selection and system integration is safe and reasonable. The main parts, laser, cladding head are imported famous brands; Machine tool adopts high precision transmission device; Box structure is firm, excellent safety performance, collocation can monitor the life of the filter element, so as to achieve long-term stable work.

Convenient operation, good plasticity

The operating system is highly integrated. Laser, machinery, dust removal and purification, powder feeder and other major systems are centralized operation, unified monitoring, can also be customized according to the need to add new functions.

innovation

Powder feeder and other core components are fully designed, which can realize the uniform distribution of various materials and help users realize more possibilities.

Excellent safety performance

The sealing device system is safe, stable, simple and reliable, with a number of monitoring interlocking devices to warn operators of the current equipment status and prevent argon gas damage; Efficient dust removal and purification method, unique filter core replacement device, effectively eliminate the risk of cleaning column damage and explosion; Laser protective glass to prevent laser damage.

Laser coaxial wire feeding equipment LiM-SW/SW-R/SW-RM

Device integration is scientific and reasonable, and the hardware and software logic of the device is refined to strictly avoid possible security problems during device installation, operation, and maintenance.

Combined with years of process research and development experience to verify and optimize equipment, we can provide customers with process technical support and equipment customization services.

Multi-system unified monitoring, friendly interactive interface.

Combined with the pre-processing software independently developed by laser, the equipment can realize more complex forming applications.

Laser cladding equipment LiM-PWAAM501/LiM-PWAAM1501/LiM-WAAM1200

Safety as the first element, from equipment accessories quality, hardware and software design logic, production and processing process monitoring and other aspects to ensure the safety of operators, equipment, parts;

Accumulated years of process service and equipment research and development experience, can also customize equipment according to customer special needs;

High integration of operating system, laser system, mechanical system, dust removal and purification system, powder conveying system and other main systems centralized operation, unified monitoring, friendly interface;

The pre-processing software system is completely independently developed, with perfect functions, convenient operation, seamless compatibility with devices, and new functions can also be developed according to special needs.

Arc additive equipment Equipment LiM-SC/SC-R/SC-RM

Low cost and high efficiency

The welding wire cost of the same material is only 1/5-1/3 of the powder cost; The material utilization rate is more than 90%, higher than other additive manufacturing; The printing efficiency can reach 550cm3/h, which is more than 50 times of SLM and more than 3 times of laser powder delivery.

High performance

The energy density of plasma arc is similar to that of laser, and the forming grains are fine. Internal metallurgy without defect, no unfused, excellent performance.

multifunctional

A equipment with forming, additive repair, welding and other functions; It can realize the additive manufacturing of aluminum alloy, copper alloy, titanium alloy, superalloy and other materials.

digitization

Equipment can automatically identify high and low points and feedback motion system, intelligent additive manufacturing; Independently developed routing software AMSlicer Pro to match the process and realize automated additive manufacturing.

Laser welding equipment LiM-W/W-R/W-RM

With many years of research and development experience of laser welding equipment and mature welding process, in order to meet the process requirements as the ultimate goal, while taking into account the convenience of actual operation of equipment.

More flexible customization, can realize the double robot collaborative welding, complete more complex tasks.

Laser, robot, wire feeder and other systems unified monitoring and operation, all processing information can be seen.

Auxiliary equipment: LiM-UZ400 ultrasonic vibrating screen divider

LiM PF001-2 powder feeder, PCE-650 powder cleaning equipment, LIM-X400 pick-up station