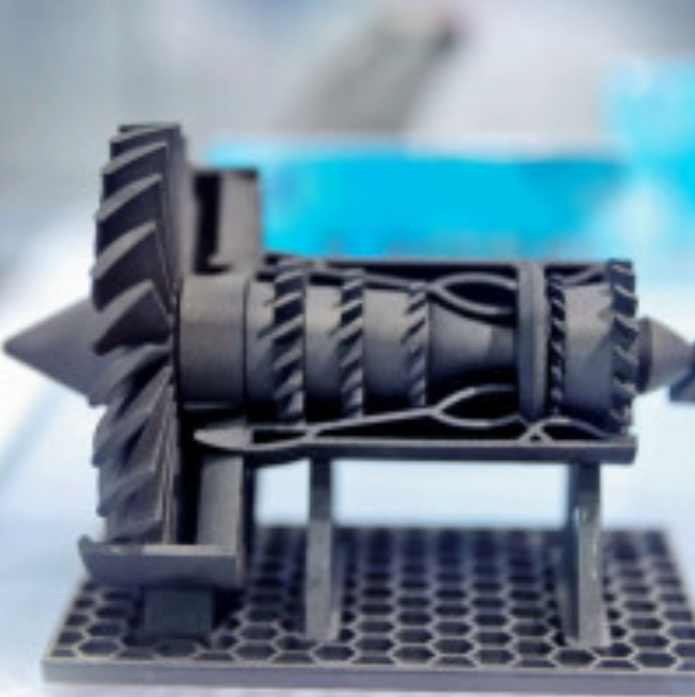

We have several selective melting equipment and large laser deposition manufacturing equipment. We can flexibly use 3D printing technology such as selective melting, laser deposition and plasma arc welding to prepare parts of any size, any structure and dozens of materials.

SLM selective laser melting technology

SLM selective laser melting technology, using layer-by-layer powder and laser selective melting method directly forming parts with specific geometric shapes according to CAD data, the forming process of metal powder is completely melted, resulting in metallurgical bonding.

LENS laser near-clean molding technology

LENS laser near-clean forming technology is an organic combination of rapid prototyping technology and laser cladding technology. It takes metal powder as raw material, uses high-energy laser beam as heat source, and melts, rapidly solidifies and deposits the supplied metal powder layer by layer according to the CAD model of the formed part, thus realizing the direct manufacturing of the entire metal part.

Laser coaxial wire feeding technology

Laser coaxial wire feeding forming, based on the unique ring optical path and coaxial supply additional filling material, welding wire can be evenly fused from all directions, and with the target location of the weld pool to obtain a good connection. Compared with the powder form of laser forming, because the material is 100% imported and processed, so the material utilization rate is very high. Even if the working distance fluctuates within a certain range, the energy can be evenly distributed in a completely annular focusing area, thus ensuring stable machining process. The main applications of the laser coaxial wire feeding process currently include high-end workpiece repair, corrosion resistant material layer, thin wall 2.5D structure generation, and large volume additive processing.

Laser cladding technology

Laser cladding technology refers to placing selected coating materials on the surface of coated matrix in different filler ways, and melting a thin layer of the surface of the matrix at the same time after laser irradiation. The cladding layer has low dilution but strong bonding force, and is combined with the matrix in a metallurgical manner, which can significantly improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance or electrical properties of the surface of the matrix material. Thus, the purpose of surface modification or repair can be achieved to meet the specific performance requirements of the material surface and save a lot of material costs. Compared with surfacing welding, spraying, electroplating and gas deposition, laser cladding technology has the characteristics of small dilution, compact structure, good combination of coating and matrix, many suitable cladding materials, large changes in particle size and content, etc., so the application prospect of laser cladding technology is very broad.